Talk about the special equipment for the valve starting and starting the valve

How to deal with valve damage?

Because the valve works in a high temperature environment, wear and burning are inevitable. Suzhou Tianzhijiao Precision Machinery Co., Ltd. is committed to the research and development of valve grinding machines, so we have some opinions on the damage of the valve, and we are here to share with you.

This happens when repairing. Usually new parts are replaced. But sometimes you can't buy the valve equipment of the same model, then you need to repair the old parts or use the valve of the close model (the valve head and the valve stem diameter are close, slightly different). If ablated, it can be used after grinding on the valve sander. If the diameter of the valve head is too large, a certain outer diameter can also be ground on the light grinder valve. The valve should be replaced with new products due to severe wear and deformation.

In addition, after the valve device is lightly polished, the edge of the valve head is also thinned, and it is more likely to be flexed and burned during use. Therefore, in general, the valve device needs to be replaced when the thickness of the valve head edge is less than 0.8 mm. If the valve head is not trapped in the valve seat, that is, when the valve head is higher than the valve seat, the valve head working surface can be ground a little. Normally, the valve should be inspected during secondary maintenance.

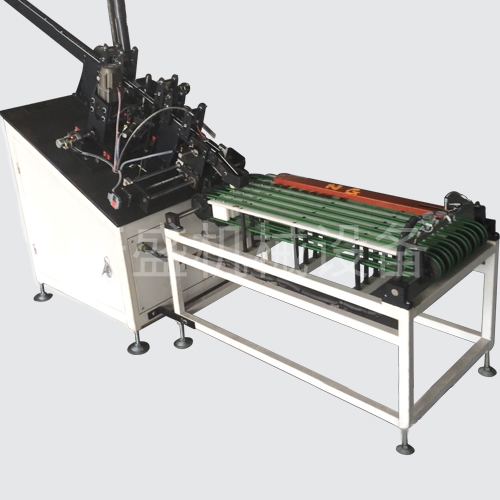

The valve grinding machine is a special equipment for processing the starting valve. According to the processing parts, it can be divided into: valve lock groove grinding machine, valve disc outer grinding machine, valve cone surface grinding machine, valve rod end surface grinding machine, and centerless grinding machine. According to the processing steps, it can be divided into: electric pick-up machine, valve rod end face quenching machine tool, valve grinding machine (the above five types), valve rod end drilling machine, plasma welding machine.

In response to the needs of our customers, Zhongshan Tiansheng Machinery Equipment Co., Ltd. has successfully developed new products. More precise, efficient, fast and safe. It adopts PLC, servo drive and automatic CNC grinding machine. Reduce labor costs while improving product quality.

How to grind engine valves?

The valve grinds the valve grinder equipment of Zhongshan Tiansheng Machinery Equipment Co., Ltd. It can grind the outer diameter of the valve disc, the lock clip groove, the rod end face, the taper surface, etc. In addition, our company also produces electric pick-up machines, plasma welders, valve full-length cutting machines and so on.

The seal of the engine cylinder requires three places: the seal between the piston, the piston ring and the cylinder; the seal of the cylinder head; the seal of the valve and the valve seat.

Valve: The valve consists of a rod and a head: the rod moves inside the duct and guides the movement of the valve; the head and the valve seat are tightly seated to ensure the seal of the cylinder.

Valve seat: The valve seat has two structural types, one is made into a separate seat and is inserted into the cylinder head; the other is directly hinged on the cylinder head. For the valve seat formed directly on the cylinder head, the valve seat has three tapered surfaces: an outer cone surface, an inner cone surface and a valve seat working cone surface. When the valve is seated, it is in contact with the working cone surface of the valve seat, and an annular contact surface is formed on the working cone surface of the valve. The width of the contact surface is 1.2-1.8 mm, and the position of the contact surface is in the middle of the working cone of the valve.

If the contact surface is too wide (that is, the working cone of the valve seat is too wide), it is easy to stick to the foreign matter and affect the sealing performance of the valve; if the contact surface is too narrow, the sealing performance will also decrease.

The address of this article:http://www.yse2yc.cn/en/news/408.html

Key word:氣門(mén)磨床,氣門(mén)車(chē)床,氣門(mén)設(shè)備

The next one:The steps and methods of valve machine fault handling are nothing more than

Recently browse:

Related products:

Related news:

- What adjusts the clearance of the valve lathe?

- Learn about the independent entry and exit of the valve lathe system

- How to make the industry of valve lathe processing rise

- Safety precautions for using valve lathes

- So how should the principle and function of the valve device be understood?

- What are the advantages of an automatic valve lathe as a guide feed thrust?

- The steps and methods of valve machine fault handling are nothing more than

- Tell me more about how the valve lathe controls the operation.

- Tiansheng Xiaobian explains to you the classification of engine variable valve equipment intake

- Main features of welding of rod end drilling machine for valve equipment