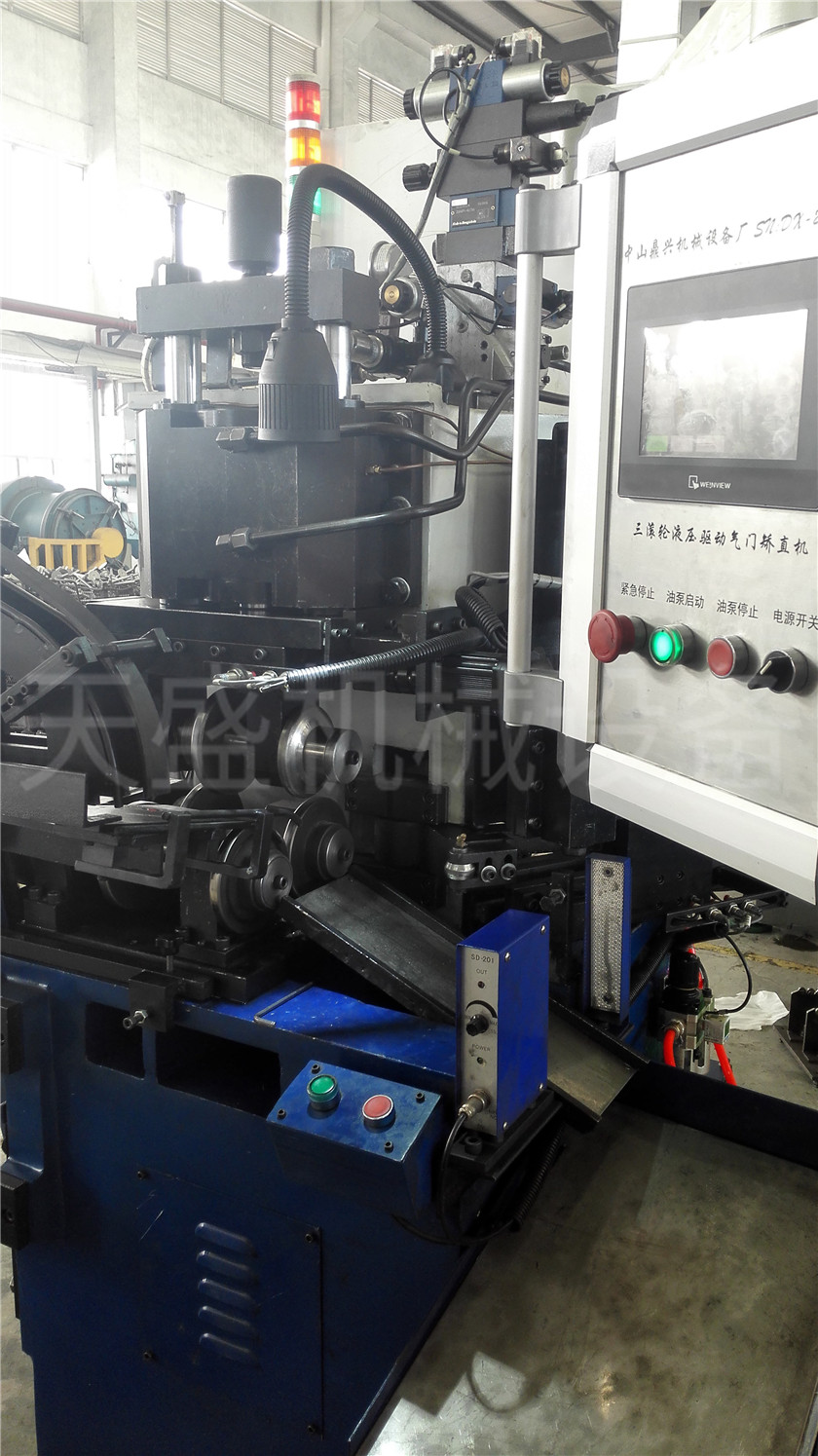

Valve head straightening machine

Taxonomy:Valve roughing equipment

- Number of clicks:

- Release date:2018/11/01

- Message

- Content

- Parameter

- Video

Header straighter

1. Processing range (original state of the workpiece):

Workpiece status | Processing conditions | Remarks |

Disk diameter | MAX 50㎜-80mm | |

Rod diameter | φ7~14㎜ | |

length | 100~250㎜ | |

Material | 21-4N+4Cr10Si2Mo | |

hardness | 30—60HRc | |

Rod beat | 1.0㎜ | |

Disk beat | 0.8㎜ |

2. Machining accuracy and beat:

Part | Accuracy | Detection method and tool |

Rod beat | MAX 0.15mm continuous processing and measuring 50 pieces | Dedicated Gage |

Disk beat | MAX 0.15mm continuous processing and measuring 50 pieces | Vernier caliper |

Processing efficiency (beat) | With the machining allowance rod diameter 9 as the standard 8s/pcs | |

3. Main configuration:

Main structural features | Quantity | ||||

bed frame | It is welded by steel plate and then annealed to prevent deformation. The symmetrical structure design greatly improves the rigidity, vibration resistance and thermal deformation resistance of the bed. | 1 set | |||

Spindle | Main motor | Gear motor 5.5KW (380V/50Hz) | 1 set | ||

Drive triangle | Chain drive | ||||

Spindle | |||||

Feed | Feed screw | Taiwan silver ball screw | Market standard parts configuration, smooth sliding resistance, high sensitivity, low noise; repeat positioning accuracy: 0.01mm | 1 set | |

Feed rail | Taiwan silver roller linear guide | ||||

Feed drive | Huichuan servo + motor | ||||

lubricating | The main shaft adopts sealed self-lubrication, no need to fill grease in 3 years; the feed is automatic lubrication oil pump, fixed point, timing, quantitative automatic lubrication, automatic oil injection pump is out of oil, automatic operation stops, alarm flashes prompt, forced refueling. | 1 set | |||

Control System | Control System | Huichuan | 1. The electrical part should have certain moisture and dustproof measures to adapt to the environment of 70% humidity work site in summer. 2. There are total accumulated numbers on the operation panel, the cumulative number of shifts, the clearing, and the production timing function. 3. The machine has a computer RS232 interface, with alarm signals, counting alarms and fault alarms. 4. The device is clearly positioned as a three-color signal light. | 1 set | |

server system | Igawa River Servo | ||||

touch screen | Huichuan | ||||

Air pressure configuration | Taiwan Yadeke | ||||

sensor | Autonics | ||||

Safety | Infrared detection | ||||

Feed | Pneumatic automatic feeding, product spacing does not collide | 1 set | |||

Discharge | Crawler type automatic discharge, product interval does not collide | 1 set | |||

use | Three-phase five-wire system 380V/50Hz, air pressure: 0.4~0.6MPa | ||||

Total power | 8kw(380V/50Hz) | ||||

Machine dimensions | 1000×1000×1800㎜ | ||||

Machine weight | 2500㎏ | ||||

Your current location:

Your current location: